High rockwell hardness numbers represent hard materials and low numbers soft materials.

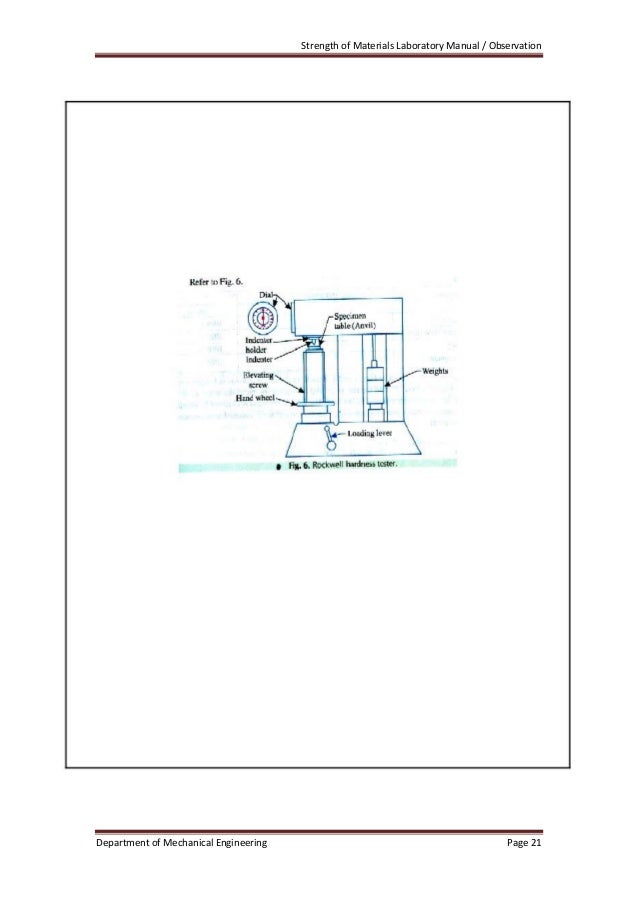

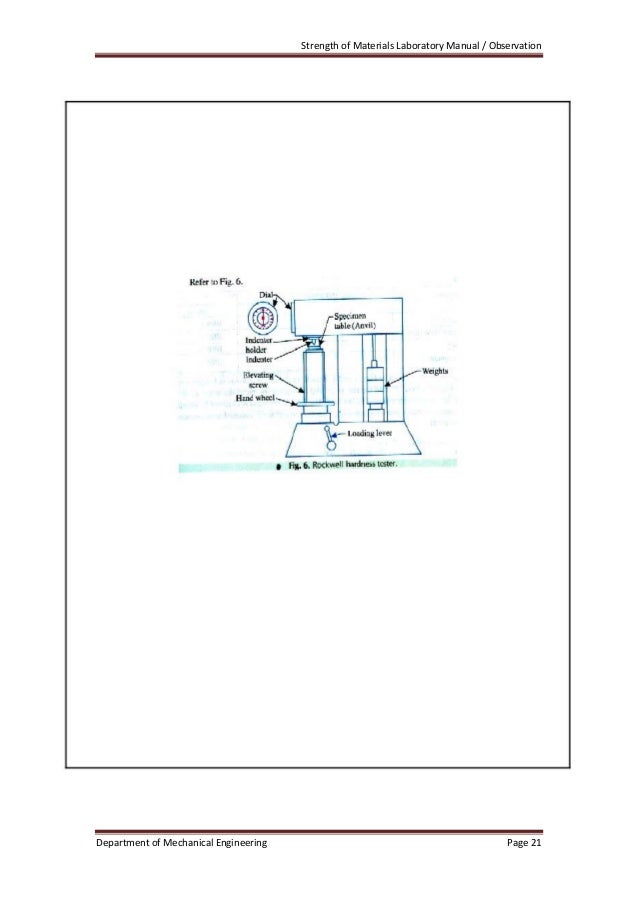

Drawing rockwell hardness testing machine diagram.

Sandland at vickers ltd as an alternative to the brinell method to measure the hardness of materials.

490 3 882 6 1373 n 50 90 140 kgf.

Principally this testing is similar to brinell hardness testing.

Portable dynamic hardness testing machines model.

Suitable for rockwell tests.

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the m c.

The vickers hardness test was developed in 1921 by robert l.

Mainly used to check hardness in confined spaces on large heavy components permanently installed parts with low test expenditure.

Handwheel cover plate 5.

Motorised for automatic operation cycle i e load dwell unload.

Indentron 400 series rockwell hardness testing system 11 1 4 tester diagram ni 400 series 1.

There are different scales denoted by a single letter that use different loads or indenters.

Common indentors are made of hardened steel or diamond.

Remote start connector optional 11.

Smith and george e.

Range lever combination units 8.

Browse our technical specifications library to find detailed specification information on rockwell automation rockwell software and allen bradley products.

The rockwell scale is a hardness scale based on indentation hardness of a material.

The vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter and the indenter can be used for all materials irrespective of hardness.

Sleek handy design comes in a slim briefcase for carrying the machine.

In all hardness tests a define force is mechanically applied on the piece varies in size and shape for different tests.

Test setup and operation 6 5 1 setting up indenter and anvil 6 5 2 selection of test load 6 5 3 load a test specimen 7 5 4 selecting time at load 7 5 5 initiating a test 7 5 6 test completion 7.

Installation see parts location diagram on page 8 4 tester footprint drawing for bolting the tester to the work table.

Elevating bearing cover 7.

The rockwell test measuring the depth of penetration of an indenter under a large load major load compared to the penetration made by a preload minor load.